end-to-end solution provider for Solid Wood, Panel Wood and specialized Woodwoking Industry

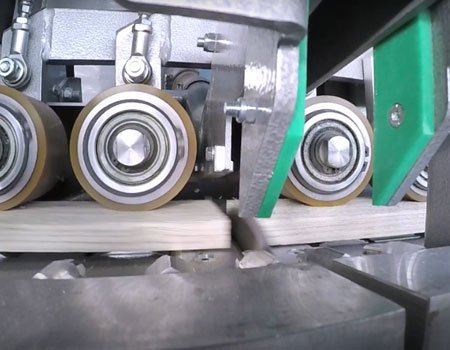

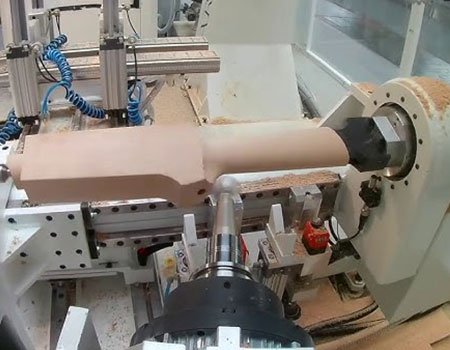

Jovas Tech Solutions an end-to-end solution provider for the solid wood, panel wood, and specialized woodworking industry, we offer a comprehensive range of products and services that cater to the entire value chain of woodworking Industry. This would include machinery and equipment for tasks such as cutting, shaping, jointing, and finishing, production planning, and quality control. Jovas Tech Solutions also provide technical support, training, and consulting services to help woodworking businesses optimize their operations, improve efficiency, and enhance product quality. Additionally, we offer customized solutions, spare parts, and maintenance services to ensure seamless production and minimize downtime, making a one-stop-shop for all woodworking needs.

Since our establishment in 2017 in Bengaluru, Karnataka, Jovas Tech Solutions has prioritized understanding the unique needs of our valued customers, consistently delivering high-quality products at competitive prices. Collaborating with reputable manufacturers in the industry, we source a range of top-notch equipment, including sawmill machines, roller coating machine lines, automatic spray coating systems, entry-level machines, sliding table panels, custom plant solutions, door frame milling machines, and high-frequency veneer press machines. To ensure customer satisfaction, we meticulously inspect all items before delivery, guaranteeing they meet our strict quality standards.