Circular Edger/Ripsaw

KME2/BM

Solid wood ripping with a rip saw is a fundamental process in woodworking, involving the use of a powerful saw to cut solid wood into narrower strips or planks along the grain. A rip saw, specifically designed for this purpose, features a blade with teeth angled to efficiently tear through the wood fibers, minimizing splintering and ensuring a smooth finish. Operators can adjust the saw's fence and blade to achieve precise control over the cutting width, allowing for accurate cuts in various wood species and dimensions. Rip saws are commonly used in woodworking shops for tasks such as cutting lumber to size, resawing thick boards, and preparing stock for furniture making, cabinetry, and other woodworking applications.

Circular Edger/Ripsaw

KME2/BM

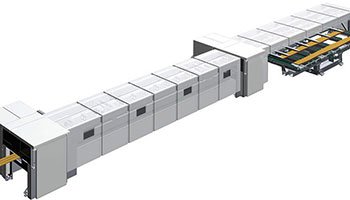

Circular Edger/Ripsaw

KME3

Circular Resaw/Ripsaw

S

Circular Resaw/Ripsaw

SGL

Flexible Rippsaw

CGL

Circular Ripsaw

Q

Manual Ripping

K34V/1000

POWER RIP

AB920/ AB-MA

POWER RIP

XAB

Straight Line Rip Saw

YRS-14/ YRS-16

Straight Line Rip Saw

YFR-303

Straight Line Rip Saw

YFR-303S

Wood manufacturing is an art form that requires skill and craftsmanship, as well as knowledge of the materials and techniques used. Throughout the years, wood manufacturing has evolved to include new and innovative methods, allowing for faster production and better-quality products. As a wood manufacturer, it is thus important to identify the wood manufacturing techniques most suitable for your business as well as the needs of your buyer personas.

“we at Jovas Tech Solutions guide you through the complete process of manufacturig and help you find the right machinery with right specification & needs keeping in mind the future enhanement.”

Copyright © 2024 - All Rights Reserved - JOVAS TECH SOLUTIONS

designed & developed by URidentity