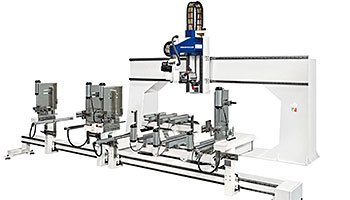

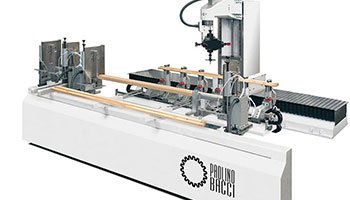

machining center with 6 interpolated axes

MASTER.TGV

Machining center is a type of automated machine tool that is designed for precision machining tasks, including milling, drilling, boring, and tapping of various materials. These centers are equipped with multiple tooling options and can perform a range of operations in a single setup, significantly improving efficiency and accuracy in manufacturing processes. Typically controlled by computer numerical control (CNC) technology, machining centers allow for complex part designs and repeatable production, making them essential in manufacturing industries. They come in various configurations, including vertical and horizontal setups, accommodating different machining requirements and workpiece sizes.

CNC portal machines, are advanced machining systems characterized by their gantry-style construction, where a bridge-like structure supports the machining spindle over the workpiece. These machines are equipped with CNC technology, allowing for precise automation of complex machining operations such as milling, routing, and engraving. The portal design provides stability and rigidity, reducing vibration and improving accuracy, making them ideal for large workpieces or intricate designs.

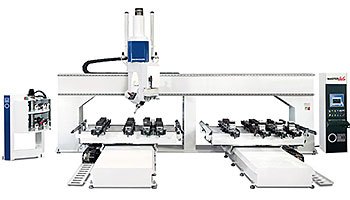

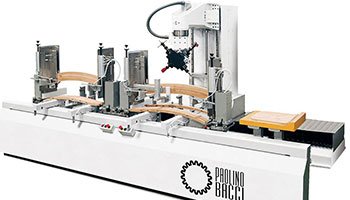

machining center with 6 interpolated axes

MASTER.TGV

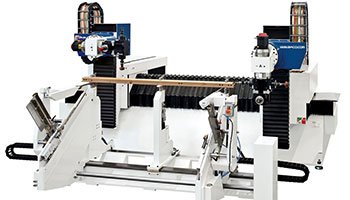

machining center with 6 interpolated axes

MASTER.FLAT - 3600

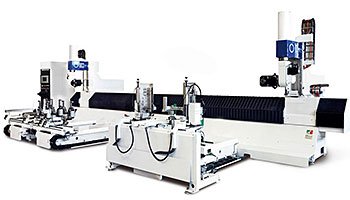

machining center with 6 or more interpolated axes

MASTER.RAIL - 5400

machining center with 6 interpolated axes

ARTIST.JET

rigid machining center with 5 axes

MASTER.MOULD / MASTER.ADVANCED

machining center with 5 axes

MASTER.WIN - 2400

machining center with 5 axes

MASTER.WIN - 4100

machining center with 6 axes

MASTER.WIN TWO

single-table machining center with 5 interpolated axes

SHARP

machining center with 6 axes

ARTIST.TGV

numerically controlled 5-axes machining center

SHARP.LINER

machining center with a Bakelite working table

ARTIST.L LPM/ ARTIST.FLAT

5-axes machining center with Bakelite working table

ARTIST.S LPM/ ARTIST.FLAT

double 3-axis machining center with 3 independent rails & pods tables

MASTER.PRO 3+3+1 RAIL

double machining center with 5+5 interpolated axes

DOUBLE.CSF2

double machining center with 6+6 interpolated and numerically controlled axes

DOUBLE.JET

double machining center equipped with two independent operating units with 5+5 interpolated axes

EVOLUTION

highly flexible machining center

EVOLUTION.JET

10-axes machining center (+ the 2 interpolated axes of the numerically controlled tool changing magazines)

MASTERPRO.5+5 FLAT

equipped with two independent working tables

EVOJET.LINER

8-axes machining center, equipped with two separate and independent working tables

AVANT

machining center with 5 interpolated axes

JET.L

machining center with 5 axes - perform in a single set-up

SMART

6-axes machining center, equipped with two independent tables - perform in a single set-up

TWIN

6-axes machining center, equipped with two independent tables - perform in a single set-up

TWIN.JET

machining center with 5 interpolated axes

JET

machining center with 5 interpolated axes

JET.LINER

5-axes machining center - performing in a single set-up

SMART.JET

Wood manufacturing is an art form that requires skill and craftsmanship, as well as knowledge of the materials and techniques used. Throughout the years, wood manufacturing has evolved to include new and innovative methods, allowing for faster production and better-quality products. As a wood manufacturer, it is thus important to identify the wood manufacturing techniques most suitable for your business as well as the needs of your buyer personas.

“we at Jovas Tech Solutions guide you through the complete process of manufacturig and help you find the right machinery with right specification & needs keeping in mind the future enhanement.”

Copyright © 2024 - All Rights Reserved - JOVAS TECH SOLUTIONS

designed & developed by URidentity