Panel Processing

Unveiling Wood Manufacturing Process & Methods

Wood-based panels are produced by chipping wood or a similar raw material and then assembling it into a panel-shaped end product. This makes it possible to use wood fractions that could otherwise only be used as raw material for pulp production or even as fuel. In this way, a comparatively inexpensive raw material is transformed into a high-quality product. Wood-based panels are an important starting material for the wood and furniture industry worldwide.

The panel processing involves a series of meticulous steps, from log selection to quality checks, to produce high-quality and durable panel. Each stage contributes to the strength, stability, and aesthetic appeal of the final product. By adhering to strict standards and incorporating advanced machinery, manufacturers ensure that their panel meets the diverse needs of the industries, offering reliable and versatile materials

Functions and features of Wood Paneling Machine

A wood paneling machine is used to produce wood panels in large quantities, automatically carrying out most of the required functions. This includes the following features:

-

Feeding System

This is where the logs are placed into the machine for processing. It has rollers that grip the wood and push it forward at a constant speed. The feeding system ensures each piece of wood paneling is the same size. It reduces the need for people to control the machine. More advanced feeding systems use sensors to measure the wood panels and adjust the speed accordingly. This eliminates jams and makes the whole thing run smoothly.

-

Cutting System

The cutting system is the heart of the machine. It turns logs into panels in a wide variety of sizes and shapes. There are circular saws, band saws, and planer knives. The cutting system is really powerful. It can take a whole log and cut it into panels in just a few seconds. It is also very precise, thanks to computer controls. The cutting system can make panels that are all exactly the same size without any waste. Advanced cutting systems use lasers to measure the wood panels as they are being cut. This allows them to adjust the speed of the saws and make sure every panel is the right size. This technology also reduces waste since there won't be any panels that are too small or uneven.

-

Conveying system

The conveying system moves the cut wood panels to the next step in the production line. It uses belts or rollers to transport the panels smoothly and steadily. The conveying system can carry a lot of panels at once. This keeps the whole machine working efficiently without any slowdowns. They are also adjustable. Factories making panels of different sizes can change the conveyor belt width to match.

-

Veneering

Veneering is a wood manufacturing technique that involves covering a base or substrate with a thin layer of high-quality wood or other decorative material, typically using adhesives. The resulting composite material is called a veneer.

Veneering is often used to create furniture, cabinetry, and other decorative wood products. Veneers can be made from a wide variety of wood species and other materials and can be cut into different shapes and sizes to achieve the desired design.

-

Glue Spreader

Some wood panels need glue to be put together properly. The glue spreader applies the adhesive evenly across the surface of the wood panels. It uses rollers or spray nozzles to cover the panel with glue in a quick and consistent manner.

-

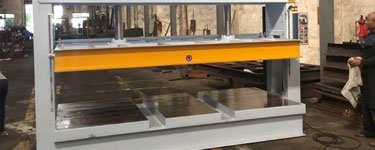

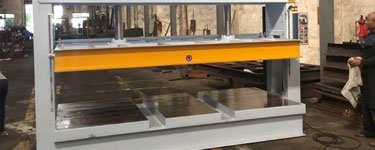

Pressing System

The pressing system helps to bond the glue to the wood panels. It uses high pressure rollers to compress the panel together for a fixed amount of time. The pressing system is really powerful. It can apply the exact amount of pressure needed to make sure the glue dries properly and the panels are nice and strong. Without the pressing system, the glued panels would not be able to dry or stick together.

-

Laminating

Laminating is a wood manufacturing technique that involves bonding multiple layers of wood together with an adhesive to create a thicker, stronger and more stable material. The resulting composite material is called laminate or engineered wood.

Laminating is often used to create structural components for buildings, furniture, and other products. It can also be used to create decorative wood panels with a wide range of textures and patterns.

"Choosing the Right Machinery & Process?"

Wood manufacturing is an art form that requires skill and craftsmanship, as well as knowledge of the materials and techniques used. Throughout the years, wood manufacturing has evolved to include new and innovative methods, allowing for faster production and better-quality products. As a wood manufacturer, it is thus important to identify the wood manufacturing techniques most suitable for your business as well as the needs of your buyer personas.

“we at Jovas Tech Solutions guide you through the complete process of manufacturig and help you find the right machinery with right specification & needs keeping in mind the future enhanement.”